Technology-Driven Development

350Intellectual Properties

Technological innovation is ensured by RoboCT’s independent R&D.

6System Authentications

Roboct’s professional and compliant operations aim to drive the industry forward.

Technology

-Driven Development

40Industrial Design Awards

Medical devices by RoboCT can be aesthetic as well as functional.

10Sci & Tech Innovation Awards

RoboCT explores new scenarios for putting technological innovations into practices.

Industry-University Collaboration

RoboCT has established joint laboratories with Harbin Institute of Technology, Harbin Engineering University and Carleton University in Canada, seperately. Through the three parties of colleges and universities, enterprises and research institutes, they will jointly promote industry-university-research exchanges and cooperation in the spirit of complementary advantage and mutual benefit. An artificial intelligence innovation task, led by RoboCT, was unveiled in 2021, and has been cooperated with universities to jointly complete the provincial key R&D project entitled "Neurofeedback-guided Interactive Exoskeleton Product".

Intelligent Manufacturing

RoboCT has the advantages of independent development and production of core components. In addition to promoting products including robot joint modules, McNamee wheel modules, and servo motion control solutions to the market and providing enterprises with total robot solutions, we also provide services such as intelligent system construction and production line modifications to put our technology into application.

Quality Control

RoboCT Changfeng Factory, with a total area of 3,000 square meters, has standardized production worskshops. It is a production complex integrating various functions such as assembly, production, quality control, procurement, warehousing, logistics, and office. At present, the factory is mainly used for the standardized supply chain management of core robot components and a series of robots such as exoskeleton, UFU, and laboratory robots.

Full Chain of Core Technologies for Exoskeletons

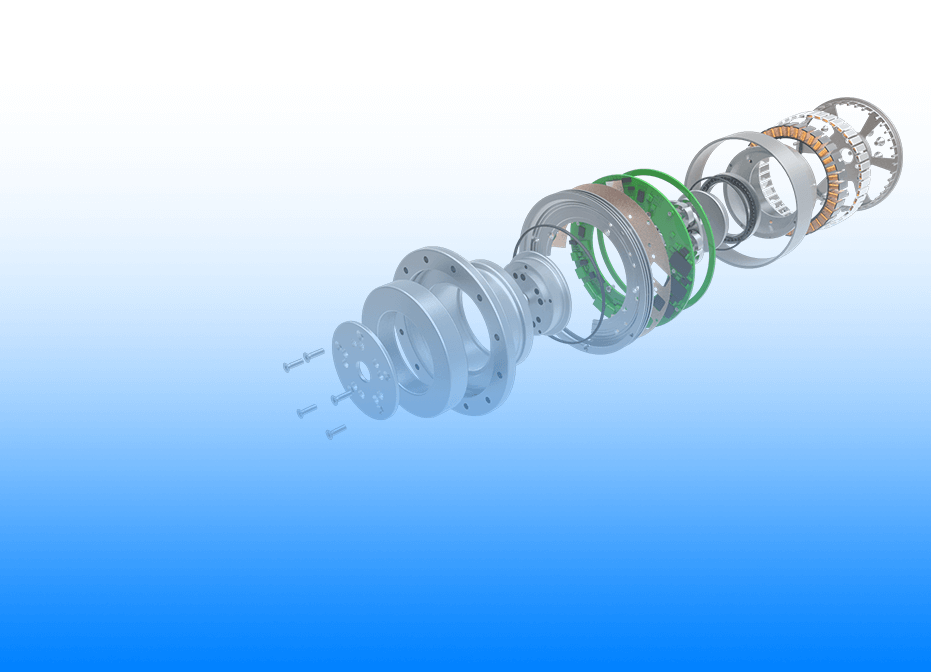

Joint Modules Joint modules with brushless servo motors, drives, gearboxes, encoders and other micromanipulation modules are adaptive for various articulated robots, bionic robots, exoskeleton robots and other precision motion equipments.

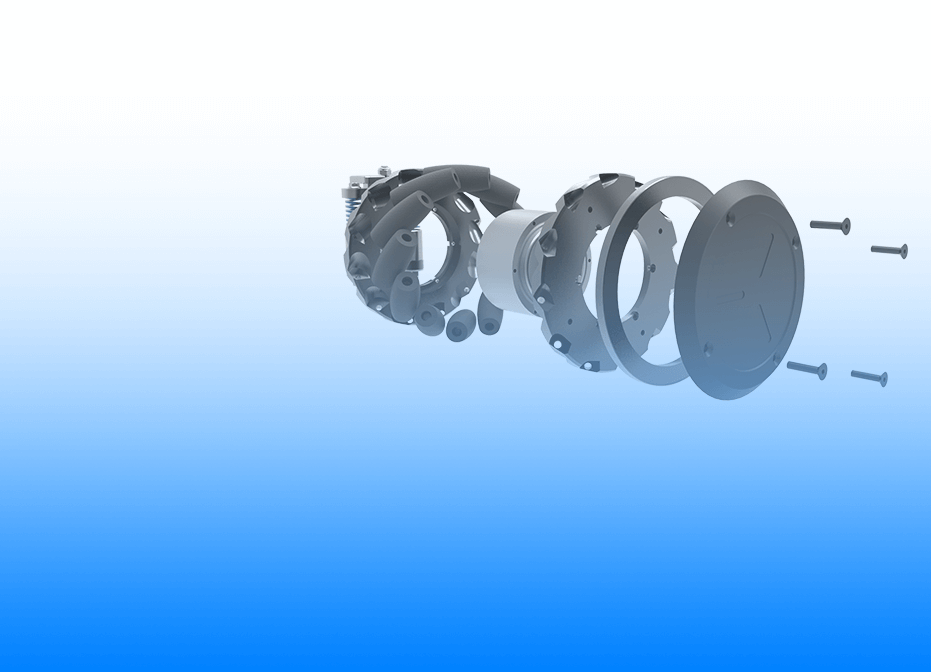

McNamee Wheel Modules The integrated McNamee wheel module is a technical improvement on the traditional McNamee wheel, integrating core components such as McNamee wheels, motors, encoders and shock absorbers into one unit. The cost-effective omni-directional assembly performs better in conveniency and stability.

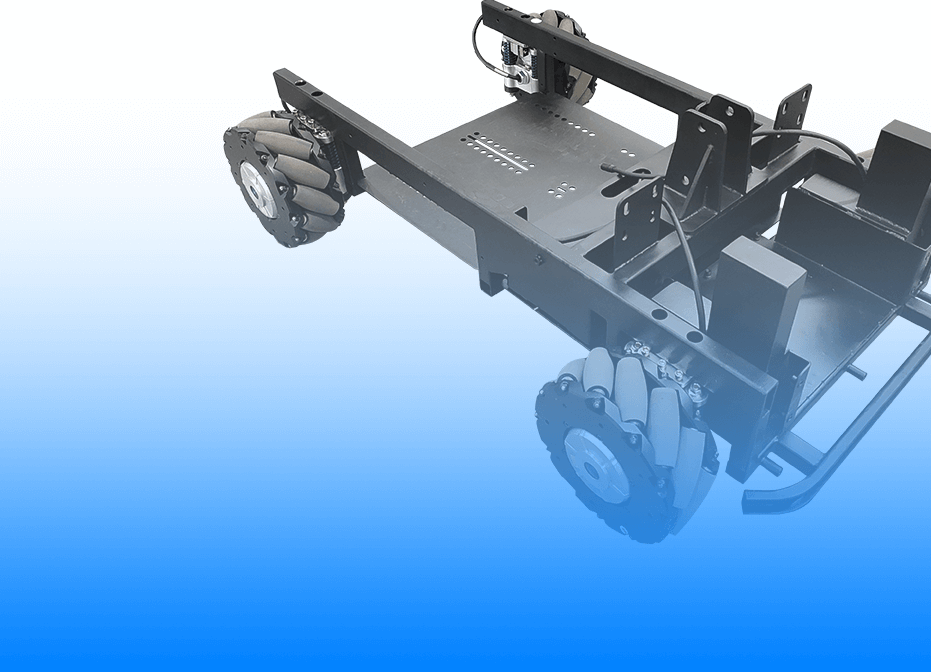

Omni-directional Mobility Based on the McNamee wheel module, AGVs, AMRs, mobile robots, and special handling equipment are equipped with special drive control and battery modules. It provides them with omni-directional mobility while ensuring stability, efficiency, as well as cost-effectiveness.